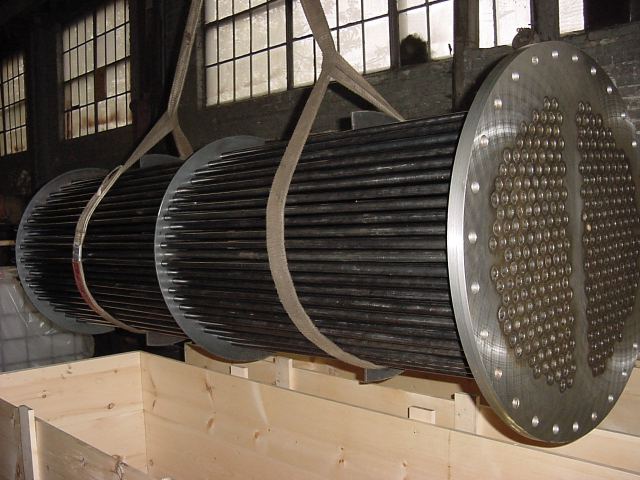

In order to ensure smooth performance of entire business, refinery, plant etc. all parts within that particular company or plant have to work perfectly. Impaired function of at least one part disturbs entire workflow. For example, heat exchangers. If they don’t work properly, all activities within certain plant or refinery suffer. Luckily, it’s possible to fix that. In order to ensure safe and proper performance, you have to make sure that heat exchangers in your refinery or plant are well-maintained. Since this equipment is delicate, it requires professional approach that can only be offered by Dunn Heat Exchangers.

The company offers a wide range of services that will improve performance of heat exchangers, as well as entire plant, and decommissioning is one of them. This highly demanding process is performed by our skilled and knowledgeable craftsmen who introduce latest industry methods and high-quality equipment to do every process successfully. The company meets latest welding requirements which is of high importance in this business.

The primary purpose of decommissioning is to securely expel site or office from administration by destroying, devastation, and decreasing lingering radioactivity onto a level which enables arrival of the property as well as end of the permit. Some decommissioning processes include devastation of entire power plants and particular dissembling of apparatus of force house gear such as heat exchangers, turbines, turbines generators, recurrence changers, static exciters etc.

The primary purpose of decommissioning is to securely expel site or office from administration by destroying, devastation, and decreasing lingering radioactivity onto a level which enables arrival of the property as well as end of the permit. Some decommissioning processes include devastation of entire power plants and particular dissembling of apparatus of force house gear such as heat exchangers, turbines, turbines generators, recurrence changers, static exciters etc.

Our company provides these decommissioning services:

- Power plant decommissioning

- Dismantle and removal of turbine generators

- Stack demolition and dismantling in power plant

- Rigging and removal of power plant equipment

- Rigging and removal of machinery and equipment.

Our highly skilled craftsmen work 24/7 in order to finish every project in timely manner and with the most positive outcome. The main goal of the company is to provide high quality service and ensure smooth performance of your equipment.

Quality of our company is confirmed by our Quality Assurance Department which ensures that every project meets the latest code requirements of TEMA and ASME. Furthermore, Dunn Heat Exchanger’s quality department is certified by the American Society of Non-Destructive Testing, American Petroleum Institute, and American Welding Society.

The benefits of trusting DunnHeat with decommissioning services are numerous, which means that you only have to contact us to get more info about the services. Also, you can schedule a plant tour and get to know more about the company itself, equipment we use, and techniques we incorporate.

Regarding more information on our Decommissioning services feel free to visit us online.